Our Work in Action

Explore how Marrowbold Innovations tackles complex challenges with precision engineering and innovative manufacturing solutions.

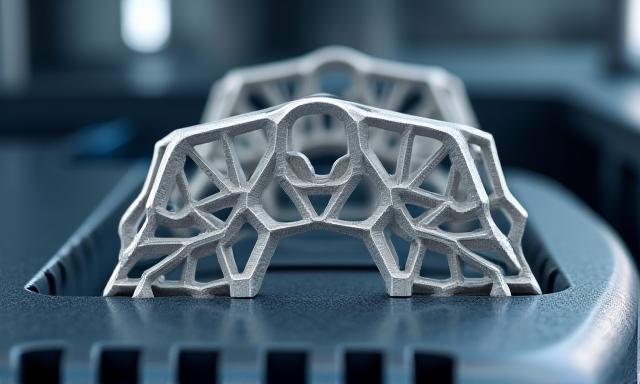

Aerospace: Lightweight Component Prototyping

Challenge: An aerospace client needed to significantly reduce the weight of a critical bracket without compromising its structural integrity or performance under extreme conditions.

Solution: Marrowbold Innovations leveraged advanced generative design software combined with state-of-the-art metal additive manufacturing (3D printing). This allowed for organic, optimized geometries that traditional manufacturing methods couldn't achieve.

Result: Successfully achieved a remarkable 40% weight reduction on the bracket, leading to improved fuel efficiency and payload capacity for the client's aircraft. The rapid prototyping also accelerated their development cycle significantly.

Medical Devices: Custom Surgical Guide

Challenge: A surgical team required a highly accurate, patient-specific guide for a complex orthopedic procedure, demanding biocompatibility and intricate design to precisely map anatomical features.

Solution: We designed and fabricated a custom surgical guide using medical-grade photopolymer via SLA (Stereolithography) 3D printing. This ensured superior surface finish, detail, and material properties suitable for medical applications, following stringent quality controls.

Result: The custom guide enabled unparalleled precision during the surgery, which led to a 25% reduction in overall operating time and improved patient outcomes. Our rapid turnaround allowed for immediate clinical application.

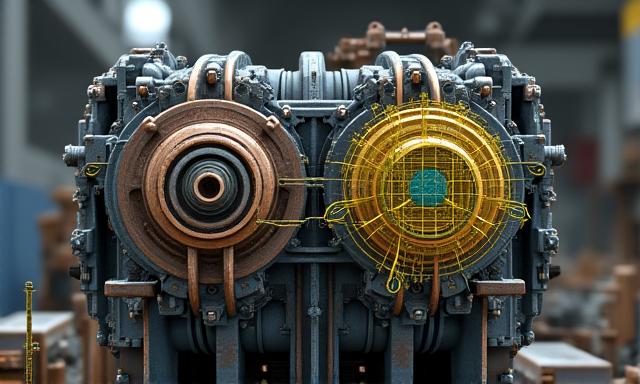

Automotive: Rapid Tooling for a New Bumper

Challenge: An automotive manufacturer needed to quickly produce a robust mold for a limited-edition vehicle bumper, facing tight deadlines that traditional tooling methods couldn't meet.

Solution: Marrowbold Innovations deployed rapid tooling techniques, utilizing high-performance polymers and composite materials to construct a durable and precise mold. This significantly shortened the production lead time without sacrificing the quality required for injection molding.

Result: The first batch of production-ready bumper parts was available in just 2 weeks, a massive acceleration compared to the typical 10-week lead time for conventional tooling. This enabled the client to launch their special edition vehicle on schedule.

Want to discuss your project? Request a Quote Today